More and more warehouses use 5s to manage warehouse pallets and goods. Many companies have successfully implemented 5s management, but some companies do not insist on 5s management. Why does the warehouse need 5s management?

Ka mua, the implementation of 5s management can solve most problems in the warehouse.

No debris, equipment, materials, and tools are stacked in the warehouse. The warehouse becomes a “debris storage place”; shelves of different sizes, warehouse trays of different sizes, and items are not arranged neatly.

The project does not have a “material transceiver registration certificate”, and the operating status is unclear. It is difficult for others to find except the parties. Spot products are stacked too high or too high, it is not easy to get started; do not follow the “low light high” “large-small low high” principle.

The goods are placed on the shelf together with the outer packaging box, which affects the uniformity of the warehouse.

Assault is difficult to clean, and clean is difficult to maintain for a long time.

The warehouse administrator’s security awareness is weak, and the preventive measures are negligent.

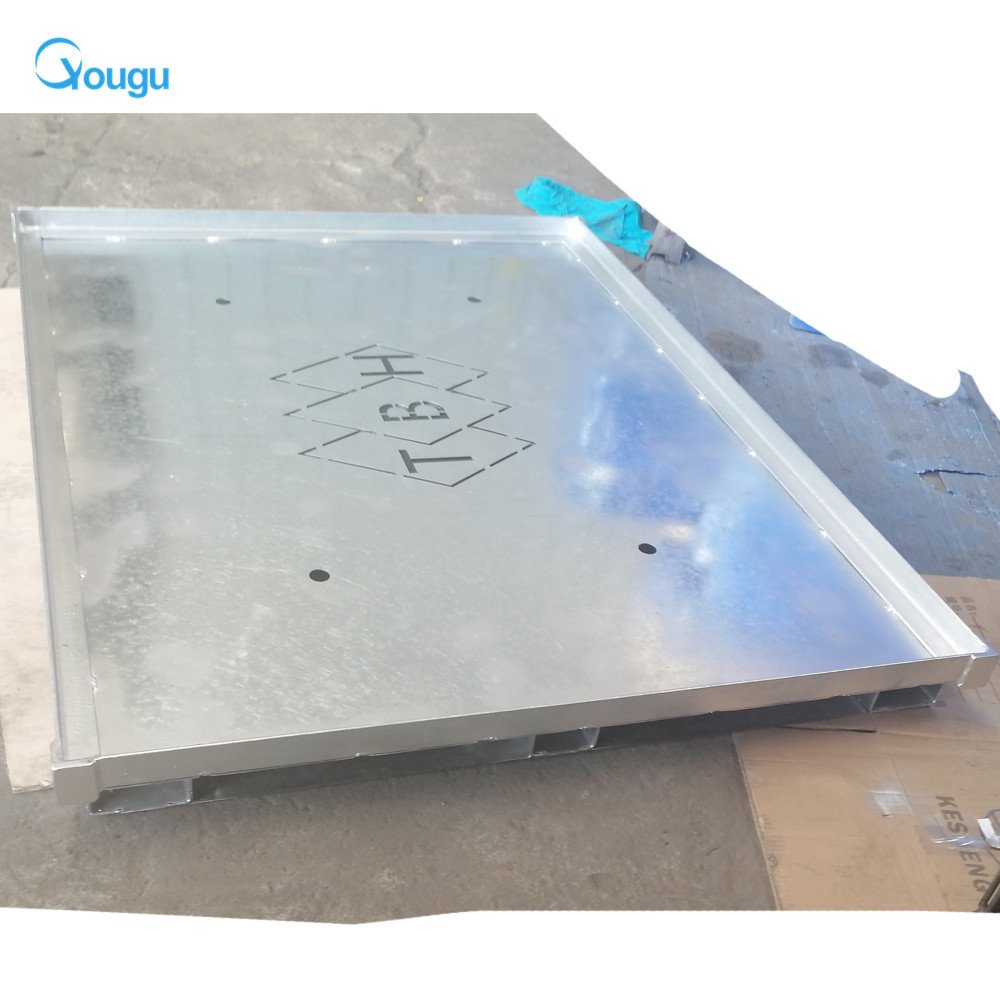

Warehouse pallets do not match the use of forklift hydraulic trucks, etc.

The above problems will cause problems such as lagging warehouse management, excessive waste, and many hidden safety hazards. It is inevitable to carry out transformation.

What are the contents of 5s management?

1. Organize

Definition: Distinguish between what is and what is not. Only important items are placed on site.

2. Rectify

Definition: The necessities of daily life according to the provisions, the setting method is neat and orderly, and the signs are clear.

3. Cleaning

Definition: a work area for removing dirt and debris within the site.

4. Clean

Definition: institutionalize, standardize, and maintain the results of organization, rectification, and cleanup.

5. Literacy

Definition: Everyone abides by the rules and regulations, develops good habits, and makes everyone an educated person.

What is the role of 5s management?

The workplace is clean and tidy. The work enthusiasm of employees has increased, more and more loyal customers, the company continues to have high popularity, many people come here to visit, study and expand the company’s popularity and sales results. Improve the quality of employees and keep the warehouse clean and safe. Employees can have a strong sense of quality. According to the production requirements, use it according to the regulations, discover the hidden dangers of quality as soon as possible, and produce high-quality products. 5S management can reduce inventory and eliminate overproduction; reduce the damage of warehouse pallets and goods. The equipment failure rate is low, reducing the search time and waiting time of the workpiece, thereby reducing costs, improving efficiency, and shortening the processing cycle. People have been implementing the regulations of matters correctly. You can start work immediately. Any work has effectively promoted standardization work and improved work efficiency. Such as reducing the number of pallets, forklifts, and other handling tools; reducing unnecessary warehouse shelves and equipment.

I ka pōkole, from two aspects of the warehouse and 5S management, it is very necessary to carry out 5S management in the warehouse, which can effectively improve warehouse-related problems, improve the competitiveness of enterprises, and reduce costs to a certain extent.

Ka manawa hoʻouna: 2020-05-02